Hot Rod Jim's Chassis Shop

|

|

|

|

Oct. 21, 2009

Waiting on the transmission to install the cab, but parts keep going on. Brake lines, fuel lines, turbo oiler lines, and fuel tank.

- Kelly Royall

|

|

|

Oct. 20, 2009

A few quickly taken photos, no, we're not normally this messy and I'll get Brianne to take some good ones before we drop the cab on.

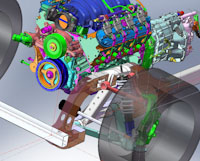

Exhaust all warped up to keep heat in the exhaust

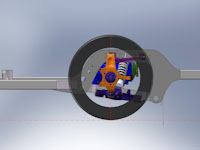

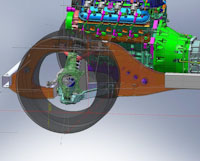

New production diff adapter, I almost have a price on these for you guys

The Vintage Air Pulley system. This thing is awesome. It came with a water pump and the lower balancer

Cab and other parts all painted up waiting on the chassis.

- Kelly Royall

|

|

|

Oct. 15, 2009

The frame just came back from the powder coat. We immediately started bolting on the suspension.

- Kelly Royall

|

|

|

Sept 20, 2009

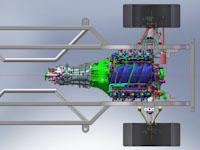

Turbos are here. I’ve only started into the kit but after I read the instruction book I had only one question. Not bad considering this is our first turbo car. We’ll be rigging the waste gate to the side pipes and the fact that these are quality turbos with remote gates. Braded lines and a plethora of fittings to make sure you have what you need for your build. Two large Oil pumps and their wiring system with integrated pressure sensors and alarms so if you have any issues with the pumps failing you’ll be alerted before you destroy something.

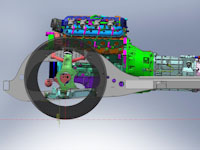

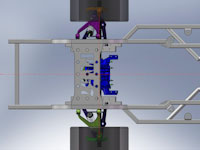

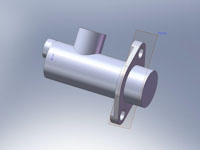

Front end went back on the truck and we started fabing the inner fenders and new firewall. We did have one minor miss hap with the steering column location but we’ve fixed it getting the column into the proper location to the driver. Even though it’s not adjustable the seat is on a slide and the pedals will be adjustable so as to get them all dialed into the driver. Headers are tight but thanks to the guys at American Racing Headers we got a set of the corvette headers and modified them to fit. I, like an idiot, had them coated first due to our time restriction, bad idea. I had to draw up my own master cylinder for the brake pedal model but not too much trouble. We’ve got the miss alignment of the pushrod down to less than 1 degree in both directions and after a quick mockup with a foam board model. Check out the exhaust going it and the rear diff adapter plate going together, this is the prototype, I know it ugly but we’ll dress is up on the mill later.

- Russell Alexander

|

|

|

Sept 14, 2009

Busy few days, some rack mockups, measurements and then back to the jig. Billy’s been getting a bunch of the little parts all knocked out and I’ve been doing paper work along with the last programming for parts off to the laser.

Fenders, wheels and fire wall, and seat checks and mockups

Billy Painted the Semi Gloss Metallic Charcoal Gray on the wheels race wheels and the street wheel.

Decided we didn't like the fire wall, really we hadn't changed it sine the move from auto the manual transmission so we needed to re adjust the position for the driver.

Back onto the jig table for driveline angling, exhaust and sheet metal work.

On the Jig with the body

Put the wheels on it for further clearances checking and just to see what she looks like

We’ll get the motor in tomorrow and go from there

- Russell Alexander

|

|

|

Sept 11, 2009

WE HAVE A FRAME. I'm off to finish putting it together.

- Russell Alexander

|

|

|

Sept 11, 2009

WE HAVE A FRAME. I'm off to finish putting it together.

- Russell Alexander

|

|

|

Sept 7, 2009

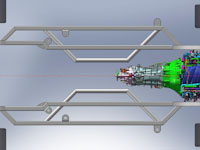

Quick update, frame quarters are almost done, the main section of the frame is knocked out on the computer, cut up waiting the quarters and the transmission is a little hung up due to some national back orders with T56 parts. Take a look at the photos, I’m going back to the work.

Remember its whats on the inside that counts. This will keep our frame from deflecting. Use structure not mass, keep it light.

- Russell Alexander

|

|

|

Aug 29, 2009

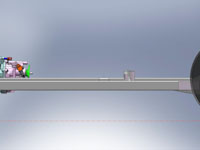

Rear frame main rails are knocked out, that’s these parts.

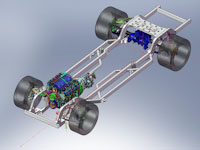

The Front batch of laser parts came in, see the erector set frame on the table. I’ve tabbed and keyed everything to make them interlocking, they’re dropping together like a kids jig saw puzzle. That means all my geometry and angles I spent all that time working out with Solidworks and suspension analyzer will be duplicated in real life in a repeatable fashion.

A little side by side for the guys who can't see it.

Brake and Clutch Pedals, Wilwood is now making this freaking cute little master cylinder with optional remote tank. Cool thing is this little bad boy has a 1.125” bore. So a pair for the brake system and one for the clutch, I’m aiming for a dual disk clutch and so the slave will need a little more fluid to disengage both clutches. I’m making a model to make designing the pedal system easier.

Turbos, Turbos, Turbos!

I can’t say enough good things about the guys at STS Turbos right now. Rick spent a day or 2 on the phone with me working out the specifics of the turbo and the design and placing of parts for optimal power. Next he went through the trouble to sort out there universal kit and pull out all the parts we didn’t need for our build and adjusted the price accordingly then specked out and supplied a cam specifically for our build. We’ll be pushing 6-7 PSI on 9.4:1 for the race making an easy 500+ HP. Considering I’m ditching the electronic cutouts and mufflers the only weight gain to the truck is the inner cooler and the compressed air piping. I’ll get more info up when our system gets here.

- Russell Alexander |

|

Page 1

Page 2

Page 3 |

|